PROJECT DETAILS

The client initially approached us via their energy supplier in 2017. They were looking for ways to improve the resilience of the stadium, lower energy costs and reduce the carbon footprint. We identified that combined heat and power (CHP) was suitable given the higher than normal heat loads presented by the under-pitch heating used in winter months and year-round demand presented by the hotel and convention centre.

The project required the design, construction, and installation of a 30m twin-bore chimney designed to match the stadium’s overall aesthetic and white cantilevered roof trusses. This chimney provided both the flue for the new CHP and a new exhaust route for the stadium’s existing standby diesel generator. The installation required:

Optimisation of the existing plant room layout to create suitable space to position the CHP, including:

- Replacing the existing single 2800 litre pressurisation unit with 6 x 500 litre units.

- Repositioning 2 pump sets.

- Modifications to existing ductwork routes.

- Changes to the lighting configuration.

- Removal of existing access door and partial removal of the external plantroom wall followed by reinstatement.

- Installation of additional CHP switch panel within the existing electrical distribution board.

- The installation was successfully completed in March 2020.

Gross CO2 saved from Sep ’20 to Mar ’22

Energy saving from Sep ’20 to Mar ’22

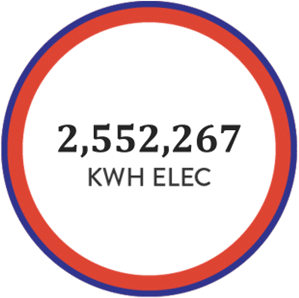

Electricity generated from Sep ’20 to Mar ’22

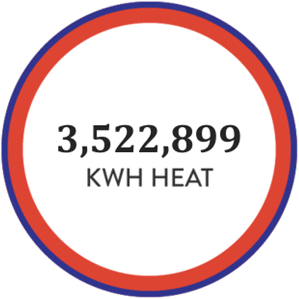

Heat generation from Sep ’20 to Mar ’22

GOALS

Improve the resilience of the stadium, lower energy costs, and reduce the carbon footprint

Electricity – lighting and power for public areas, bedrooms, and hotel facilities

Heat – hot water production for space heating and leisure facilities

Air conditioning systems – used to keep rooms and whole complex cool

CHALLENGES

Size and complexity of the site

The design, construction, and installation of a 30m twin bore chimney

The Chimney had to match the stadium’s overall aesthetic and white cantilevered roof trusses

Internal plant location

SOLUTIONS

Implemented: “EuroSite Power On-Site Utility Solution”

Tedom Cento 350

30m twin bore chimney

Additional CHP switch panel within the existing electrical distribution board

“We needed a solution that delivered both operational cost savings and reduced emissions. The fact EuroSite Power could also provide this without any capital expenditure from us made it an even better solution.”